If you are looking for an experienced plastic fabricator in the United States, it’s important to find one whose standards align with yours. Before you begin your research, decide which priorities of service you care about the most, and then narrow down the field for U.S. plastic fabricators by doing some research.

5 Questions to Answer as You Are Looking for a U.S. Plastics Fabricator

In order to find the right fabricator for you, begin your research online and ask others in the industry for recommendations. As you are trying to narrow down the field, answer the following questions about each of the U.S. plastics fabricators you are considering.

1. Can the company complete your specific project?

The first step is clear. Review the websites of all of the prospective U.S. plastics fabricator to make sure they can provide you with what you need. Some companies have limited services, while others have a multitude of resources.

2. Does the company excel at supplying projects quickly?

Your customers expect their products on time, and in turn, the fabricator should be able to supply your products according to a strict timetable. In addition to satisfying customers, a quick turnaround time means less time and resources wasted, which ultimately increases your ROI.

3. How much experience does the company have?

The level of experience is key. U.S. plastics fabricators who have been in business for many years understand principles and techniques more thoroughly than those with less experience.

The company should also have a core focus on creating solutions for your particular industry. The more the fabricator works with a specific industry, the more it can provide assistance, customization, and support that applies to that industry.

4. Does the fabricator have a large inventory of supplies?

Whether you need a project developed from conception to completion or you are looking for existing supplies, the company should have enough inventory on hand to satisfy the requirements of your project.

5. Can materials be custom cut and fabricated to strict machined specifications?

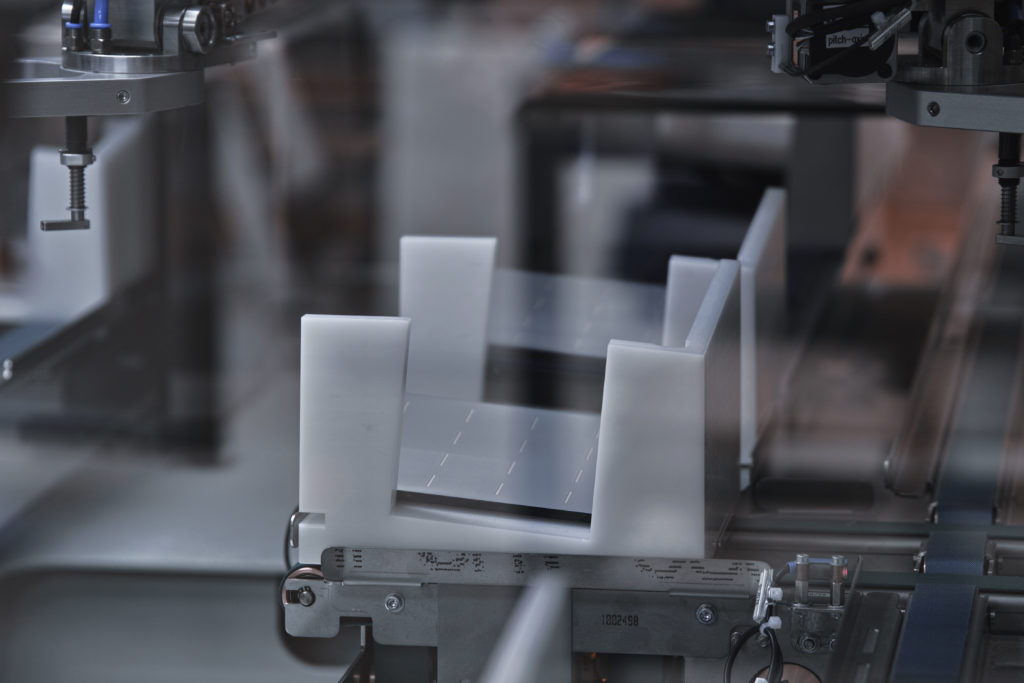

Another important aspect to look for is quick access to specialized custom fabricated plastic machined components.

The shop should be fully equipped, and the team should have extensive knowledge in machining and polishing a wide variety of plastics, such as polycarbonate, acrylic, acetal, nylon, ABS, PVS, and more.

How Polymershapes Offers the Expertise You Need

As an experienced plastic fabricator in the United States, Polymershapes aims to help customers with efficiency, expertise, and reliable customer service. We are a one-stop resource for a wide variety of solutions, so you don’t have to find a second company to work with. Our wide range of services include routing, drilling, acrylic welding, flame polishing, and more.

Our fabrication company also works with many industries, including those in the construction, retail, manufacturing, military vehicle, public transportation, recreational vehicle, and oil and gas fields. As a result, we focus on understanding each of these industries, especially as it applies to current events and industry advancements.

Contact us for more information about any of our products or services.