The Plastics Pyramid: A Guide to Plastic Material Selection

Various types of plastic products have worked their way into an array of industries. Some are used as cost-effective alternatives, while some are used to improve safety. There are hundreds of material options available, each with their own characteristics and capabilities. Manufacturers and distributors alike use an in-depth material selection process to determine which specific material is best based on its end use.

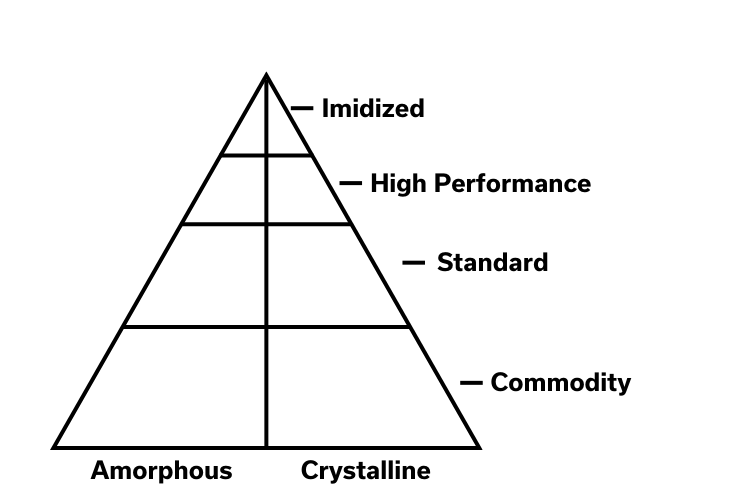

Plastics are also organized into an engineering plastics pyramid, also known as a material selection guide. It divides all the core material options into specific classes based on their qualities and capabilities. The plastic guide along with the material selection process helps quickly determine which materials are a good fit for an application.

The Different Types of Plastics

The material guide is divided into various types of plastics. Each section outlines the amount of material options based on their temperature tolerances, their polymer chain structure, and other qualities. It is designed to categorize materials into specific categories and showcase the differences between each material. The core types of plastics include:

- Imidized

- High-Performance

- Standard

- Commodity

- Amorphous/semicrystalline

- Thermoplastics/thermosets

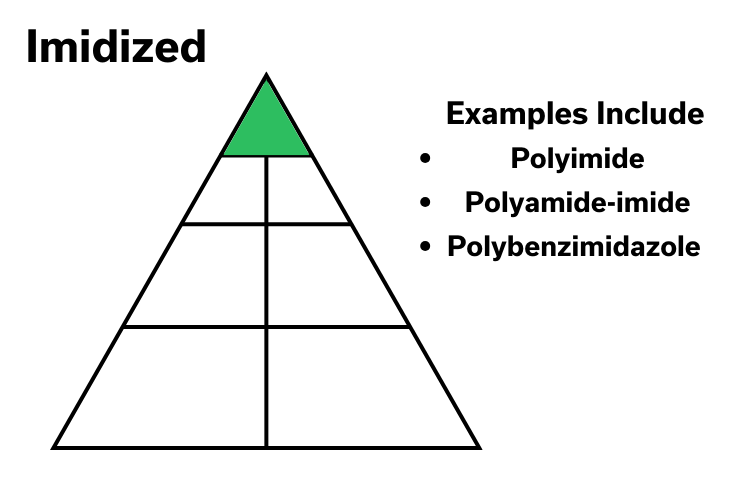

Imidized Plastics

Imidized plastics are among the strongest materials available for use. They feature the highest temperature tolerances of all plastics, with service temperatures that can exceed 500°F (260°C). They have excellent weight-bearing and wear capabilities, especially in extreme temperatures. Due to their intense manufacturing process, they tend to have the longest lead times and are usually made as they are needed.

Imidized materials are often used in extremely demanding applications that have very strict guidelines and highly technical needs. They are often used as high-performance thermal insulation, bearings, and other high-stress applications, particularly in aerospace.

Properties of Imidized Plastics

- Service temperatures that can exceed 500°F (260°C)

- Extremely high wear, temperature, and chemical resistances

- Extreme load-bearing capabilities

- Extreme creep resistance (long service life)

- Difficult to manufacture

Examples of Imidized Plastics

- Polyimide (PI)

- Polyamide-imide (PAI)

- Polybenzimidazole (PBI)

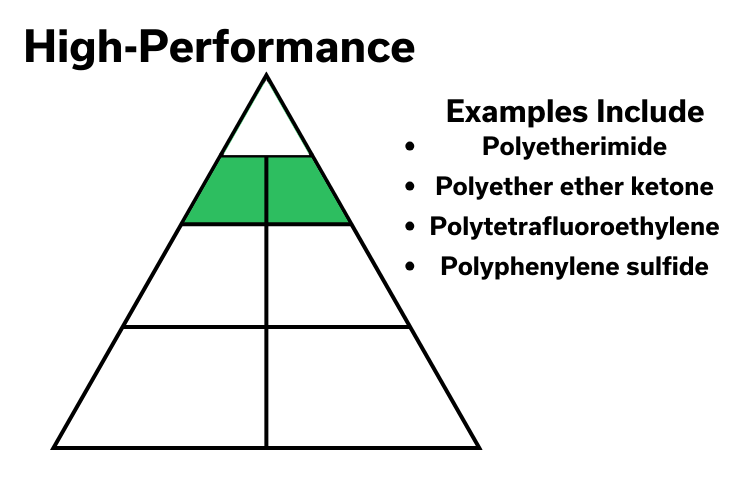

High-Performance Plastics

High-performance plastics are a step below Imidized. They feature high heat resistance of up to 250°F (120°C). They have high strength and oftentimes high purity. They’re used for applications that require high tolerances and have very specific needs. Many High-Performance material options generate operate well with chemicals and work well in steam/hot water applications.

Their very high temperature resistance and strength make them the go-to materials for a wide range of industrial applications, including machine components. They are also common in industries with heavy regulatory restrictions, such as healthcare, food & beverage, waste management, and more.

Properties of High-Performance Plastics

- Service temperatures up to 350°F (120°C)

- Very high strength

- High purity

- High chemical resistances

Examples of High-Performance Plastics

- Polyetheretherketone (PEEK)

- Polyetherimide (PEI)

- Polyethersulfone (PESU)

- Polyphenylsulfone (PPSU)

- Polysulfone (PSU)

- Polyphenylene Sulfide (PPS)

- Polyacrylate (PAR)

- Polyvinylidene Fluoride (PVDF)

- Perfluoroalkoxy (PFA)

- Fluorinated Ethylene Propylene (FEP)

- Polytetrafluoroethylene (PTFE)

- Ethylene tetrafluoroethylene (ETFE)

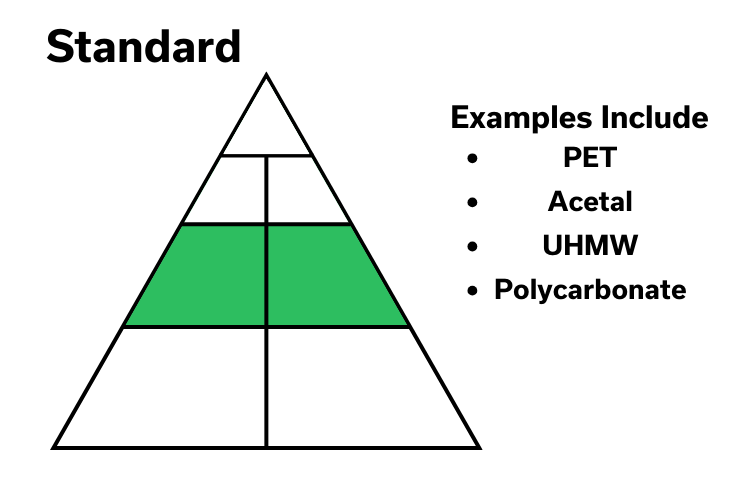

Standard Plastics

Standard plastics feature some of the more well-known plastics. They are generally easier to produce than High Performance or Imidized materials. Because of this, they are usually mass produced, cost-effective alternatives for less demanding applications. Standard materials are good general-purpose materials where strength and durability are necessary.

Properties of Standard Plastics

- Service temperatures up to 250°F (65°C)

- Good impact strength and chemical tolerances

- Good general-purpose materials

- Easier to fabricate and machine

Examples of Standard Plastics

- Polycarbonate (PC)

- Polyphenylene Oxide (PPO)

- Polyurethane (PU)

- Nylon/Polyamide (PA)

- Acetal/Polyoxymethylene (POM)

- Polyester/Polyethylene Terephthalate (PET)

- Polybutylene Terephthalate (PBT)

- Ultra-High Molecular Weight Polyethylene (UHMW-PE)

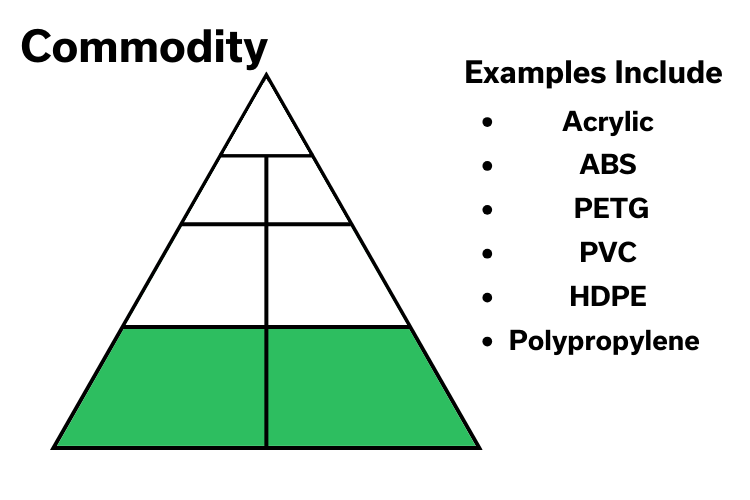

Commodity Plastics

At the bottom of the plastic material selection guide is the Commodity class. This class contains some of the most common types of plastics people encounter in everyday life. These materials generally have the lowest temperature tolerances, and can greatly vary in strength and durability. They generally have some of the shortest lead times, and are mass produced for use in many consumer-based applications.

Commodity-level plastics are generally used in applications where strength is not an immediate concern. They are generally easier to produce and recycle than plastics products higher on the pyramid.

Properties of Commodity Plastics

- Service temperatures up to 150°F (65°C)

- Low/moderate strength

- Good formability and bondability

- Very easy to fabricate and machine

Examples of Commodity Plastics

- Acrylic/Polymethyl Methacrylate (PMMA)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate Glycol (PET-G)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Polymethyl pentene (PMP)

Amorphous and Semi-Crystalline Plastics

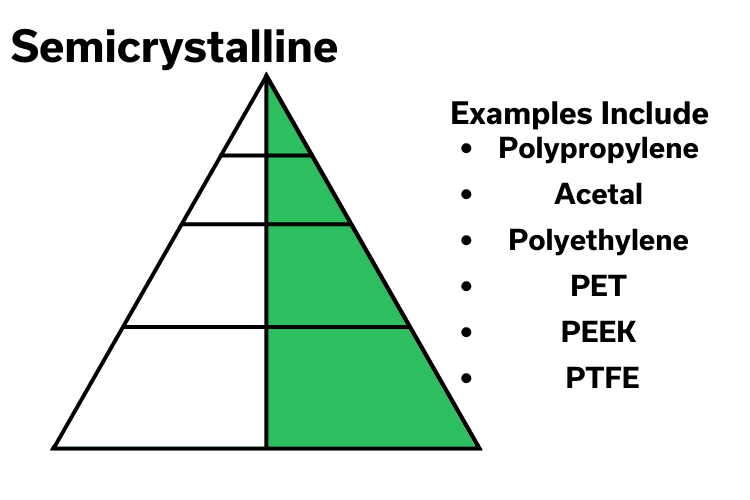

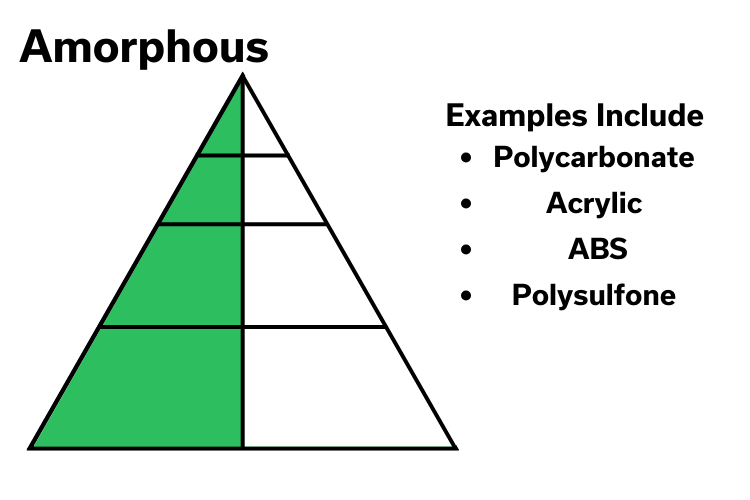

The plastic pyramid material guide lists plastics top to bottom according to their temperature capabilities. However, each side of the pyramid is also split, according to molecular structure. Amorphous plastics are on one side, with semi-crystalline materials listed on the other. The organization of a material’s polymer chains can have a significant impact on its capabilities. Visit our Amorphous vs Semicrystalline blog to learn more about the difference between the two.

.

Thermoplastics vs Thermosets

Plastic materials are also classed as thermoplastics or thermosets. Whether a material is a thermoplastic or a thermoset will determine how the material interacts with high temperatures. Thermoplastics melt, while thermosets burn.

Although the plastics pyramid doesn’t specify what each material is, the materials in the bottom half are generally thermoplastics, with thermosets being more common at the top. Visit our Thermoplastics vs Thermosets blog to learn more.

Learn More with Polymershapes

There are hundreds of plastic materials available for use, with a wide range of qualities and capabilities. The plastics pyramid is a condensed and simplified guide. It is meant to give a general idea of which materials may suit certain applications.

Polymershapes’ material selection process is more in-depth, intensive process designed to find the best material for any application. To learn more about which materials are best for you, contact a Polymershapes expert today.