Looking for your plastic fabrication tips for 2020? If you utilize plastic fabrication services for your business, it’s important to stay up to date with the latest industry trends and technological advances that might impact your company. The equipment and materials uses, as well as changes to the entire landscape of the industry, can ultimately impact the efficiency of service and the quality of your completed materials. Understanding these changes and how they might impact your business can help you gain a competitive advantage and ultimately improve your own operations.

Looking for your plastic fabrication tips for 2020? If you utilize plastic fabrication services for your business, it’s important to stay up to date with the latest industry trends and technological advances that might impact your company. The equipment and materials uses, as well as changes to the entire landscape of the industry, can ultimately impact the efficiency of service and the quality of your completed materials. Understanding these changes and how they might impact your business can help you gain a competitive advantage and ultimately improve your own operations.

For those who have used plastic fabrication for years or those who are just getting into the industry this year, here are some of the most important things you should be aware of in 2020.

Demand For Plastic Manufacturers Keeps Going Up

Plastics offer a ton of benefits, both for businesses and end users. They’re durable, easy to customize, and largely recyclable, which keeps costs down and offers a level of sustainability that both consumers and businesses appreciate. This has led to a very popular and sizable market for plastics fabrication through the years. And that demand is increasing even more.

The recent increase in market activity is due to a variety of factors. For example, improved technology and equipment has made it possible for plastics suppliers to manufacture materials and customize them in a way that suits the exact needs of customers, making them more competitive against other raw materials. This has also allowed manufacturers to offer cost effective solutions that appeal to companies throughout the world. And the global increase for plastic materials should ultimately lead to positive changes for the companies that utilize performance plastics in their operations.

Why Speed Matters More Than Ever

Today’s market also requires vendors to offer speed and efficiency to clients. Businesses that utilize plastics need to be able to receive materials and customizations in a timely manner so they can support their own operations and stay competitive in their given market. Waiting days for a quote or standing by for weeks at a time while fabricators process orders, complete customizations, and ship items is no longer an option. This can cause companies that utilize plastics to fall behind the curve, waste time checking order statuses, and lose favor with customers who want to receive products or services right away.

Ensuring That Your Fabricator or Distributor Is A Good Fit For You

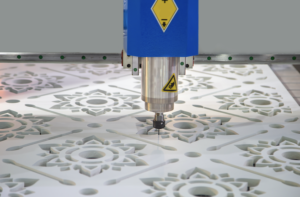

In order to choose the right plastics fabricator for your needs in 2020, you need to start by evaluating the things that are most important to your operations. Do you need specific types of modifications, like those that are only possible with state of the art equipment like CNC machines? Do you need a vendor that responds to inquiries and orders quickly so you can receive your items almost immediately after placing an order? Do you need access to a team full of industry experts that can help guide you to the materials and solutions that are going to be able to support your endeavors.

Luckily, there are plastic fabricators and distributors out there that can offer all of these benefits to your business. But it’s important that you ask the right questions and continually evaluate your needs through the years. As your business grows, it’s entirely possible that a vendor that suited you in years past may no longer be able to offer the level of service, speed, or quality that your company needs to continue its growth. At that point, learning about the market and finding a fabricator or distributor that is able to meet your needs can help you step up to the next level.

What Does A Competitive Market Mean For Your Project’s Bottom Line

Ultimately, a competitive plastics market is great news for companies that utilize high performance plastics throughout their operations. This means you have more choices to find vendors in your area that are well suited to the very specific needs of your company, whether you value speed, efficiency, transparency, or quality above all else.

Increased competition also means that fabricators have more motivation than ever to continue innovating and making improvements to their operations. If they want to gain your business, they need to find ways to stand apart from the competition. This may mean integrating new equipment or technological advances to improve speed. It could mean improving industry knowledge and training to offer better insights to clients. Or it could mean improved materials and quality that ultimately get passed down to end users. Regardless of the specifics, it’s clear that today’s plastic fabrication vendors are more apt than ever before to provide materials and service that are especially well suited to the needs of customers.

If you’re looking for a plastics fabricator that can meet all of your quality, efficiency, and service goals in 2020, contact Polymershapes today. We offer a variety of fabrication and customization options to ensure that your plastics are able to meet your exact needs in terms of size, visibility, strength, and durability. Since we’re a nationwide distributor, we can bring customers a high level of product quality and a large variety of materials. However, we also have local facilities to deliver fast quotes and order processing along with personalized service and unbeatable product knowledge. Our selection includes polycarbonate, polypropylene twinwall, vinyl, nylon, acrylic, PVC, and so much more. To get in touch with our friendly and knowledgeable customer service team to get started with your next order, visit our branch locator online.