Whether you need a component or a finished part, Polymershapes leverages our network of 80+ locations, and partner vendors to offer you CNC routing, turning, milling, and plastic fabrication & finishing services. From simple and elegant retail displays, to complex industrial parts with tight tolerances, the team at Polymershapes is ready to help meet your specifications with speed and accuracy!

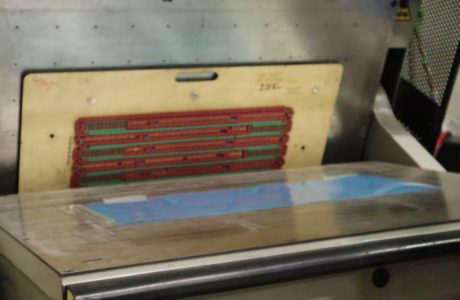

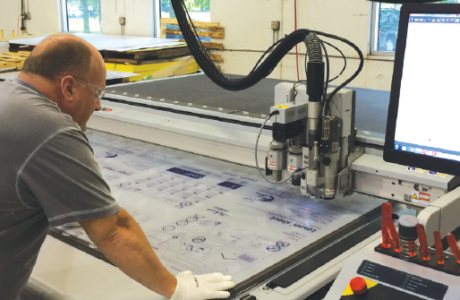

CNC Routing

With custom job support and turn-key service, Polymershapes can provide CNC routing services with tight tolerances for a wide range of part sizes. Through our network of in-house and partner facilities, we offer precision camera guided cutting and routing, post-print cutting services, and 3-axis routing. With material specific profiles, your material will be cut with superior edge quality, with accuracy and consistency. Polymershapes is also available as an over-flow vendor, for our customers that have their own in-house routing and cutting services.

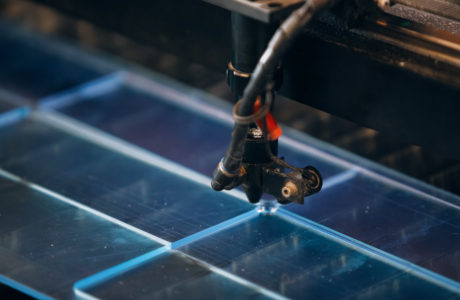

Laser Cutting

For tight tolerances, with a clean finished edge, laser cutting services are available in select facilities.

CNC Turning & Milling

CNC turning and milling services are available in the Polymershapes network via select facilities and partner vendors. From prototyping, to one-off parts, or higher volume production, Polymershapes can help you with the most complex and intricate parts.

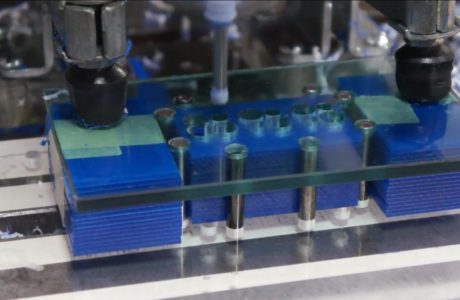

Drilling

For smaller part runs, or prototyping, drill press services are available to form holes in a variety of materials. For larger runs, routing services may be recommended.

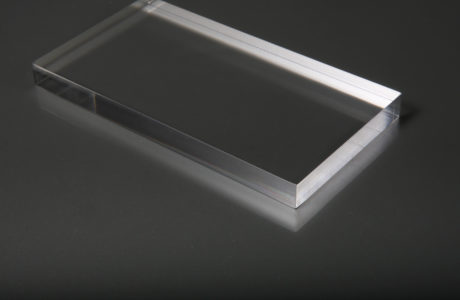

Plastic Edge Finishing and Polishing

During plastic fabrication, plastic sheets are cut-to-size and then rough saw cut edges might be finished to a smooth edge in several ways, including diamond polishing or flame polishing. Whether you need a smooth edge on a sneeze guard, or an edge is being prepped for cementing, Polymershapes offers a variety of edge finishing and polishing services to meet your specifications.

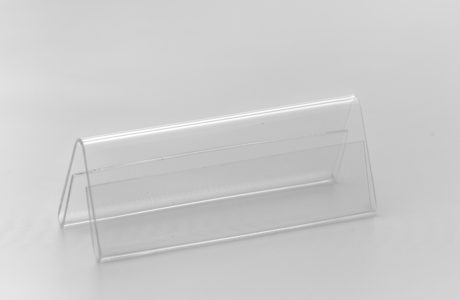

Plastic Bending

To achieve 90 degree angles, odd angles, or subtle bends and arches, heat bending and cold bending are available. Depending on the material being formed, a heat strip may be used for heat bending, or a manual or hydraulic press for cold forming.

Assembly

For finished or semi-finished parts, assembly services are available after materials have been cut, routed, bent, or edge finished. Cementing or welding can affix two pieces of material together to form a final part.

Die Cutting

For thin gauge, or film materials, die cutting may be performed to quickly produce high-volumes of parts and components with extreme accuracy and repeatability.