When it comes to transparent materials, the choice isn’t just about seeing through something — it’s about what that material can handle, how it performs under pressure, and what it can be turned into. Whether designing for safety, visibility, or aesthetics, selecting the right sheet product is key to long-term success.

At Polymershapes, we work with customers every day who are choosing between polycarbonate, acrylic, and glass. While they may look similar at first glance, the differences run deeper — and those differences matter when you’re building for the real world.

Impact Resistance

Trusted in the most demanding environments, polycarbonate is built to take a hit. With impact resistance up to 250 times that of standard glass, polycarbonate doesn’t just outperform — it outlasts.

Polycarbonate offers peace of mind in environments where breakage isn’t an option, from transit shelters and protective barriers to machine guards and skylights. It won’t shatter. It won’t splinter. It is virtually unbreakable.

Acrylic, on the other hand, offers good impact resistance—10 to 20 times stronger than glass—but it can crack under extreme force. It’s a solid choice for applications that need lightweight strength without the industrial-level durability of polycarbonate.

Fabrication Flexibility

Clear sheet materials typically aren’t used or installed as-is; they’re often transformed. The ease with which you can cut, route, drill, or thermoform these materials can differentiate between a smooth build and a costly bottleneck.

Clarity, Weight, and Weatherability

All three materials offer excellent clarity—but only two do it without adding weight or complexity.

- Polycarbonate and acrylic are roughly half the weight of glass, making them easier to install, transport, and support—especially in overhead or unsupported configurations.

- Acrylic leads in light transmission, offering a crisp, high-gloss finish.

- Polycarbonate delivers high clarity with added toughness. It’s also available in UV-stabilized and abrasion-resistant grades, so it performs outdoors just as well as indoors.

Scratch Resistance

Acrylic offers a good balance of clarity and surface hardness. It resists scratches better than standard polycarbonate and holds up well in display settings.

Polycarbonate, while incredibly tough, is softer by nature. However, abrasion-resistant grades with hard coatings are available, especially for applications where cleaning or contact is frequent.

The key is choosing the right material for the demands of your space—not just how it looks on day one.

Cost Considerations

It’s tempting to evaluate materials by price per square foot, but the real cost is in the installation, the lifespan, and the long-term performance.

Acrylic is often the most cost-effective for general-purpose applications where impact strength is helpful but not mission-critical.

Polycarbonate may carry a higher upfront cost, but it’s often the smarter investment when you factor in reduced breakage, faster installs, and lower replacement rates.

And glass? Even if the material is less expensive, the labor, hardware, and risk of breakage can quickly erode the value.

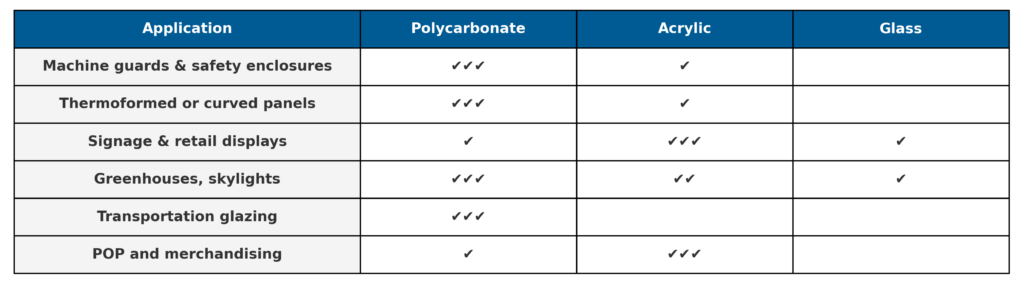

Applications at a Glance

Polymershapes: Your Partner in Material Selection

With access to the most trusted brands in the industry—including LEXAN™, OPTIX®, AZCARB, PALSUN, ACRYLITE and more —Polymershapes has the inventory, expertise, and fabrication support to help you get your project done right.

Our team can cut-to-size, route, polish, or form material to your exact specs. And with 85+ locations across North America, you get local service with national reach.

Every application is different. But when you need a material that’s strong, formable, and built for real-world use, polycarbonate stands out. It offers unmatched durability, incredible flexibility in fabrication, and long-term value across countless industries.

Not sure what’s right for your project? Let’s talk.

Polymershapes is here to help you make the right call—with the products, the knowledge, and the service to back it up.