Polycarbonate, also referred to as PC, is a tough, impact-resistant, virtually unbreakable material used in wide variety of applications. It is an amorphous thermoplastic material, with a continuous use temperature range of up to 265° F (129° C). LEXAN™ is one of the most commonly recognized polycarbonate brands.

Benefits of LEXAN™ Polycarbonate Sheets

Impact resistant

Optical quality

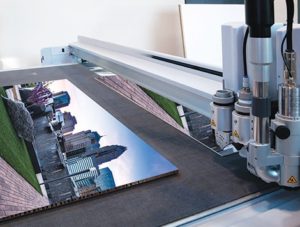

Printable

Formable

Lightweight compared to glass

FDA compliant (grade specific)

Low moisture absorption

High strength and stiffness

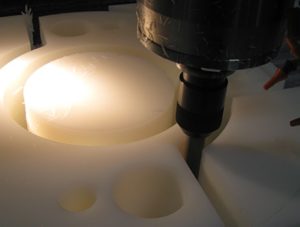

Easy to machine

Low friction

Technical Resources

- Polycarbonate vs. Acrylic vs. Glass: What’s the Best Fit for Your Project?

- PVC vs CPVC: Which Is Better?

- Polypropylene vs. Polyethylene: How Do They Differ?

- Thermosets vs Thermoplastics: How They Differ

- Homopolymer vs Copolymer

- Plastics Pyramid

- Amorphous vs Semicrystalline

- Fiber Reinforced Panel Alternatives

- How To Choose the Right Plastic for Your Project

- LEXAN™ CLINIWALL™: Next Generation Wall Cladding

- BioPhorum, Polymershapes, and the Future of Material Sterilization

- Design for Manufacturability and Its Importance

Common Applications

-

Aerospace

Aerospace

-

Armored Vehicle

Armored Vehicle

-

Automotive

Automotive

-

Bearings & Bushings

Bearings & Bushings

-

Building & Construction

Building & Construction

-

Bullet/Blast/Wind Resistant Security Windows, Doors, Enclosures and Glazing

Bullet/Blast/Wind Resistant Security Windows, Doors, Enclosures and Glazing

-

Bus & Rail

Bus & Rail

-

Bus/Transit Shelters

Bus/Transit Shelters

-

Data Centers & Aisle Containment

Data Centers & Aisle Containment

-

Die Cutters

Die Cutters

-

Electric & Non-Printed Sign

Electric & Non-Printed Sign

-

Electrical Applications

Electrical Applications

-

Enclosures

Enclosures

-

Food & Beverage Preparation/Processing

Food & Beverage Preparation/Processing

-

Forestry and Lumber Plastics

Forestry and Lumber Plastics

-

Golf Cart Windshields

Golf Cart Windshields

-

Greenhouses

Greenhouses

-

Heavy Equipment

Heavy Equipment

-

Machine Guards

Machine Guards

-

Machine Shops

Machine Shops

-

Marine Applications

Marine Applications

-

Membrane Switches

Membrane Switches

-

Milling & Mining

Milling & Mining

-

Movie Studio/Sound Stage

Movie Studio/Sound Stage

-

Packaging & Conveying Equipment

Packaging & Conveying Equipment

-

POP/Display

POP/Display

-

Printing/Graphics

Printing/Graphics

-

Recreational Vehicles

Recreational Vehicles

-

Skylights

Skylights

-

Storm Protection

Storm Protection

-

Thermoformers

Thermoformers

-

Watercraft

Watercraft

-

Window Glazing

Window Glazing

Physical Properties

| Units | ASTM Test | General Purpose Polycarbonate | ||

|---|---|---|---|---|

| Tensile strength @ break @ 73°F | psi | D638 | 7,310 – 10,700 | |

| Flexural modulus @ 73°F | psi | D790 | 250,000 – 417,000 | |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.1 – 18 | |

| Deflection Temperature Under Load @ 264 psi Unannealed | ft-lbs/in of notch | D658 | 249 – 282 | |

| Coefficient of linear thermal expansion (CLTE) | (in/in F) | D696 | 3.2E-5 to 3.9E-5 | |

| Compressive strength | psi | D695 | 9,000 – 12,500 | 9,000 – 12,500 |

| Coefficient of friction | D1894 | 0.060 – 0.39 | ||

| Taber Abrasion Resistance | mg | D1044 | 9.90 – 10.8 | |

| Water absorption – 24 hours – 1/8″ thick | 0.036 – 0.11% | D570 | 0.15 – 0.21 | |

| Deflection Temperature Under Load @ 264 psi | °F | D648 | 277 – 289 | |

| Compressive strength | psi | D695 | 9,000 – 12,500 | 9,000 – 12,500 |

* Technical Data is provided courtesy of UL Prospector (www.ulprospector.com) and IAPD (www.IAPD.org).

Data is to be considered representative and is provided for guidance only. All product performance must be verified by the user under actual application conditions.