While there are many common types of building materials, many projects have specific requirements for qualities where performance plastics can shine. Some projects may require advanced scratch resistance, or storm protection, while others need to promote long-term safety. However, all of them need heavy-duty materials that can perform.

Polymershapes can equip your next project with high quality plastic building materials that will not splinter, warp, rot, or delaminate. Building and construction plastics provide UV and corrosion resistance, impact resistance, and other qualities that protect the integrity of your construction project.

Polymershapes is a leading North America distributor of industrial quality building and construction plastic sheets. With the long list of building materials in the construction industry, plastic has become an integral part of the process. To invest in high quality plastic products, contact a Polymershapes representative today.

Common Benefits for Construction Plastics:

- Lightweight and high impact strength

- Hailstone and hurricane resistant

- Weather and UV resistant

- Transparent/high light transmission

- Will not splinter, warp, rot, or delaminate

- Wear resistant

- Easy to clean

- Thermal insulation

- Easy to fabricate

- Flame-rated materials that meet the ASTM E-84 Class A

Plastics Used in Building and Construction

The plastics that are most often found in building and construction include:

- Polycarbonate (PC)

- Acrylic (Poly-Methyl Methacrylate, PMMA)

- Aluminum Composite Material (ACM)

- High-Density Polyethylene (HDPE)

- Polypropylene (PP) Twinwall

- Polyvinyl Chloride (PVC)

Polycarbonate (PC)

Polycarbonate is one of the most widely-used building materials due to its strength and durability. It is a virtually unbreakable construction material that has become a common substitute for delicate materials such as glass or certain metals. Our distribution centers carry standard LEXAN 9034 used in a multitude of glazing applications, as well as UV-resistant grades, solar tints, and more. Polycarbonate is often a crucial component of sound barriers, glazing, outdoor cabinetry, and other elements that require durability or wear resistance.

LEXAN™ MARGARD™ is best for outdoor applications that require enhanced abrasion, scratch, or mar resistance, such as bus shelters. For greenhouses or aisle containment, LEXAN™ THERMOCLEAR™ may be the best material. LEXAN™ CLINIWALL™ is SABIC’s wall-cladding solution. CLINIWALL™ is a sanitary wall-cladding material designed for sterile environments, such as hospitals, laboratories, schools, airports, and more. CLINIWALL™ features an anti-bacterial shield designed to protect occupants in the space.

Polymershapes Polycarbonate Partners

PolymerOutdoor is a division of Polymershapes that offers Plaskolite’s Topgal multi-wall polycarbonate for pergola covers, patio covers, and more. It features an innovative standing-seam panel system designed to prevent leaks or seam gaps. Visit PolymerOutdoor to learn more.

Insulgard Security Products is a division of Polymershapes with a vast inventory of polycarbonate-based products designed for storm shelters, safe rooms, transaction windows, entry systems, and more. Visit Insulgard to learn more about their security-grade polycarbonate solutions.

Acrylic (Poly-Methyl Methacrylate, PMMA)

Acrylic sheets are available in a variety of patterns, finishes, colors, or even mirrored grades for all sorts of applications. Acrylic is a common building construction material used for its optical clarity and lightweight features. We offer flame-rated materials that meet the ASTM E-84 Class A standard, making compliance with various building codes. Acrylic is popular for applications involving natural light or optical needs, such as glazing, aisle dividers, barriers, tanks/cases, and more.

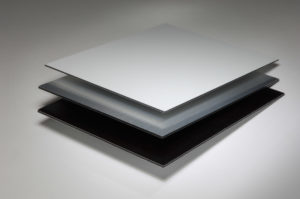

Aluminum Composite Material (ACM)

Aluminum composite materials are rigid materials designed to provide improved stability to buildings, along with an array of other qualities. Aluminum composite materials can be developed to add fire protection, improved strength, and an array of other traits. Along with its building qualities, it is highly customizable, with an array of colors that can best fit your design.

Polymershapes is a leading distributor of 3A Composites’ ACM material. Their latest product, MONARC, is a premium ACM material. Designed to be lightweight, durable, and waterproof, MONARC is a Class-A fire-rated ACM product that can mimic some of the most popular building materials, such as stone, tile, or wood. To learn more, contact a Polymershapes distribution center near you.

High-Density Polyethylene (HDPE)

HDPE plastic is one of the most widely-used types of plastic for applications requiring strength and versatility. Its lasting strength makes it the ideal material for many applications throughout a building or construction project. It has been rising in popularity as an alternative material to lumber.

While wood and lumber can be expensive and require constant maintenance, HDPE building materials are UV resistant, water resistant, and rigid across all kinds of environmental conditions. Lastly, it resists cracking or splitting, adding sustainability and reliability with lower maintenance. HDPE is also a recyclable material, making it an environmentally-friendly alternative to other options.

One of HDPE's single largest applications is plastic pipe systems. HDPE pipes feature chemical resistance and anti-leaching properties. Its durability gives the pipes a long service life. Investing in high-density polyethylene pipes prepares the plumbing system for an array of materials.

HDPE in construction is also commonly used as plastic construction barriers (such as in bus shelters), bathroom partitions, outdoor furniture, cabinetry, and more.

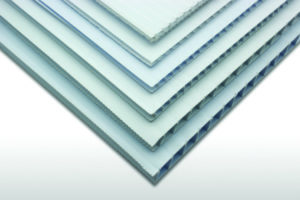

Polypropylene Twinwall (PP)

Twin wall polypropylene, under brands such as Cor-X or Coroplast, is a corrugated plastic sheet that is more durable than cardboard and fiberboard. These reusable corrugated plastic sheets are easy to cut, wear and water-resistant, and easy to bend into custom molds.

This lightweight and cost-effective material is the go-to solution for countertop templates, temporary floor coverings, and concrete molds.

Polyvinyl Chloride (PVC)

PVC materials are widely revered for how well they can hold up against weathering and moisture exposure. It comes with safety benefits and features, including chemical resistance and non-conductive qualities. It's popular for being a lightweight, long-lasting solution to applications that require water/moisture resistance.

PVC sheets are commonly used as wall cladding, concrete molds, and more. Polymershapes is a leading distributor of industrial plastics. Contact a representative today to learn more about our inventory of PVC plastic material.

Common Applications for Building Plastics

- Aisle containment

- Barriers and partitions

- Bus shelters, specialty enclosures

- Cabinet doors

- Carports

- Caulking and sealants

- Closet/pantry doors

- Commercial, institutional, and residential greenhouses

- Concrete molds

- Countertop templates

- Entryway canopies

- Floor coverings

- Mirrors

- Patio tabletops

- Piping

- Protective shields/coverings for machinery

- Privacy windows and screens

- Roof membranes

- Security windows, hurricane glazing and shutters

- Siding

- Skylights

- Sound barriers

- Temporary floor coverings

- Wall cladding

Contact Polymershapes' Construction Plastics Specialists

Polymershapes is a leading distributor of heavy plastic sheeting for construction and building applications. Plastics are a lightweight, durable alternative to common building materials used across the industry. We have a wide selection of plastic materials that provide qualities such as tensile strength, load-bearing capabilities, fire resistance, and more. To learn more about which materials may be best for your building application, contact a Polymershapes expert today.

PTFE (Polytetrafluoroethylene)

PVC-Acrylic

Silicone and Adhesives

Phenolic/Thermoset Plastics

Polyurethane (PU)

PETG (Polyethylene Terephthalate Glycol)

Bullet/Blast/Wind Resistant Security Glazing

Expanded Foam PVC

Nylon (Polyamide, PA)

Ultra High Molecular Weight Polyethylene (UHMW)

Interlocking PVC Panels

LEXAN™ Polycarbonate Sheets

Acrylic (Polymethyl Methacrylate, PMMA)

High Density Polyethylene (HDPE)

Low Density Polyethylene (LDPE)

Aluminum Composite Material (ACM)