HDPE (High Density Polyethylene), part of the polyolefin family of materials, is a semi-crystalline thermoplastic material, with a continuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is categorized as a standard material, and offers high impact strength, high chemical resistance, and very low water absorption.

Benefits of High Density Polyethylene (HDPE)

Chemical and corrosion resistant

Highly impact resistant

Abrasion resistant

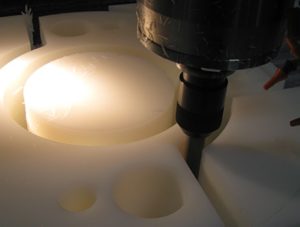

Easy to process (fabricate, weld, machine)

Thermoformable

Low water absorption

Technical Resources

- PVC vs CPVC: Which Is Better?

- Polypropylene vs. Polyethylene: How Do They Differ?

- Thermosets vs Thermoplastics: How They Differ

- Homopolymer vs Copolymer

- Plastics Pyramid

- Amorphous vs Semicrystalline

- Fiber Reinforced Panel Alternatives

- How To Choose the Right Plastic for Your Project

- LEXAN™ CLINIWALL™: Next Generation Wall Cladding

- BioPhorum, Polymershapes, and the Future of Material Sterilization

- Design for Manufacturability and Its Importance

- PETG – Markets Served and Industry Applications

Suppliers / Brands

Common Applications

-

Armored Vehicle

Armored Vehicle

-

Automotive

Automotive

-

Bearings & Bushings

Bearings & Bushings

-

Building & Construction

Building & Construction

-

Bullet/Blast/Wind Resistant Security Windows, Doors, Enclosures and Glazing

Bullet/Blast/Wind Resistant Security Windows, Doors, Enclosures and Glazing

-

Bus & Rail

Bus & Rail

-

Chemical Processing

Chemical Processing

-

Countertop Templates/Cabinetry

Countertop Templates/Cabinetry

-

Die Cutters

Die Cutters

-

Electric & Non-Printed Sign

Electric & Non-Printed Sign

-

Food & Beverage Preparation/Processing

Food & Beverage Preparation/Processing

-

Healthcare / Medical

Healthcare / Medical

-

Heavy Equipment

Heavy Equipment

-

Hoppers & Bed Liners

Hoppers & Bed Liners

-

Machine Shops

Machine Shops

-

Marine Applications

Marine Applications

-

Medical Packaging

Medical Packaging

-

Milling & Mining

Milling & Mining

-

Movie Studio/Sound Stage

Movie Studio/Sound Stage

-

Oil & Gas

Oil & Gas

-

Orthotics

Orthotics

-

Packaging & Conveying Equipment

Packaging & Conveying Equipment

-

Plastic Storage Tanks

Plastic Storage Tanks

-

Playground Equipment

Playground Equipment

-

POP/Display

POP/Display

-

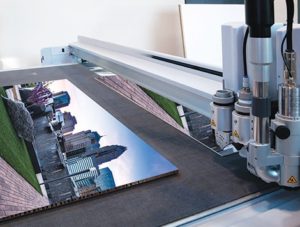

Printing/Graphics

Printing/Graphics

-

Prototyping & Tooling

Prototyping & Tooling

-

Recreational Vehicles

Recreational Vehicles

-

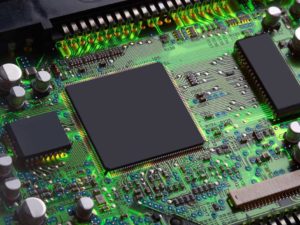

Semiconductors & Electronics

Semiconductors & Electronics

-

Sporting Goods

Sporting Goods

-

Valves & Fittings

Valves & Fittings

-

Watercraft

Watercraft

-

Wear Strips

Wear Strips