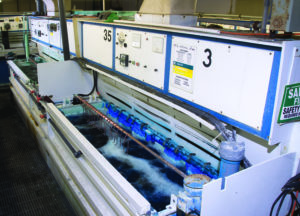

Materials used in applications in the chemical, oil and gas segments typically must meet very specific performance requirements. The right plastic can ensure a safe, durable, long-lasting performance even under the harshest conditions. Semi-crystalline materials that perform in conditions rated as “engineering” or “advanced engineering” are usually specified, as is flexible tubing for transfer and delivery needs. Resistance to chemicals, corrosion and heat are key attributes.

Plastics are used in many applications within chemical processing, including:

- Air Exchange/Compressed Air

- Bushings, Bearings, & Insulators

- Chemical Containers, Scrubbers, & Distribution Boxes

- Manifolds

- Nozzles

- Oil/Grease/Hydraulic Controls

- Pump & Valves

- Pump Components, Couplings, & Fittings

- Seats, Seals, & Rings

- Waste Water Components

- Water Purification & Lines

ECTFE (Ethylene Chlorotrifluoroethylene)

PVDF (Polyvinylidene Fluoride)

PPSU (Polyphenylsulfone)

PTFE (Polytetrafluoroethylene)

PPS (Polyphenylene Sulfide)

PI (Polyimide)

Polyester (PET)

Polyurethane (PU)

PAI (Polyamide-imide)

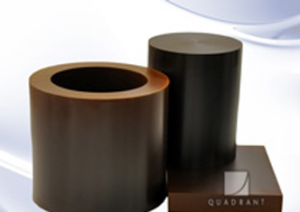

PEEK (Polyetheretherketone)

PEI (Polyetherimide, ULTEM™)

PETG (Polyethylene Terephthalate Glycol)

Ultra High Molecular Weight Polyethylene (UHMW)

Industrial PVC/CPVC

ABS (Acrylonitrile Butadiene Styrene)

Interlocking PVC Panels

Acetal (Polyoxymethylene, POM)

High Density Polyethylene (HDPE)