Nylon is one of the original engineering thermoplastic materials. With an ideal balance of strength and toughness it finds use in a wide variety of industries and applications.

Benefits of Nylon (Polyamide, PA)

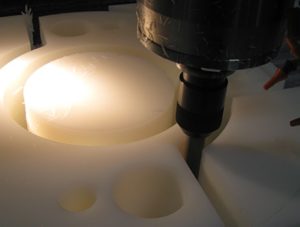

Easy to machine due to its size options/near-net shapes

Lightweight

Wear resistant

Strength/durability

Highly impact resistant

Chemical resistant

Technical Resources

- Polycarbonate vs. Acrylic vs. Glass: What’s the Best Fit for Your Project?

- PVC vs CPVC: Which Is Better?

- Polypropylene vs. Polyethylene: How Do They Differ?

- Thermosets vs Thermoplastics: How They Differ

- Homopolymer vs Copolymer

- Plastics Pyramid

- Amorphous vs Semicrystalline

- Fiber Reinforced Panel Alternatives

- How To Choose the Right Plastic for Your Project

- LEXAN™ CLINIWALL™: Next Generation Wall Cladding

- BioPhorum, Polymershapes, and the Future of Material Sterilization

- Design for Manufacturability and Its Importance

Suppliers / Brands

Common Applications

-

Aerospace

Aerospace

-

Armored Vehicle

Armored Vehicle

-

Automotive

Automotive

-

Bearings & Bushings

Bearings & Bushings

-

Building & Construction

Building & Construction

-

Bus & Rail

Bus & Rail

-

Die Cutters

Die Cutters

-

Electrical Applications

Electrical Applications

-

Food & Beverage Preparation/Processing

Food & Beverage Preparation/Processing

-

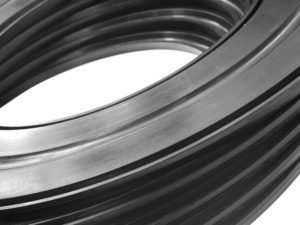

Gaskets & Seals

Gaskets & Seals

-

Gears

Gears

-

Healthcare / Medical

Healthcare / Medical

-

Heavy Equipment

Heavy Equipment

-

Machine Shops

Machine Shops

-

Milling & Mining

Milling & Mining

-

Oil & Gas

Oil & Gas

-

Outrigger Pads

Outrigger Pads

-

Packaging & Conveying Equipment

Packaging & Conveying Equipment

-

Prototyping & Tooling

Prototyping & Tooling

-

Recreational Vehicles

Recreational Vehicles

-

Sheaves

Sheaves

-

Sporting Goods

Sporting Goods

-

Valves & Fittings

Valves & Fittings

-

Watercraft

Watercraft

-

Wear Strips

Wear Strips

Physical Properties

| Units | ASTM Test | Cast NYLON | Extruded NYLON | |

|---|---|---|---|---|

| Tensile strength @ break @ 73°F | psi | D638 | 5,680 – 16,200 | 5,700 – 18,300 |

| Flexural modulus @ 73°F | psi | D790 | 81,500 – 492,000 | 218,000 – 544,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 0.79 – 2.9 | 0.64 – 1.9 |

| Coefficient of linear thermal expansion (CLTE) | (in/in F) | D696 | 1.6E-5 to 6.0E-5 | 3.1E-5 to 5.4E-5 |

| Compressive strength | psi | D695 | 1,420 – 16,000 | 1,420 – 16,000 |

| Coefficient of friction | D1894 | 0.04 – 1.4 | 0.056 – 0.37 | |

| Taber Abrasion Resistance | mg | D1044 | 3.5 – 10.1 | 4.0 – 24.0 |

| Water absorption – 24 hours – 1/8″ thick | 0.036 – 0.11% | D570 | 0.53 – 2.0 | 0.59 – 1.3 |

| Deflection Temperature Under Load @ 264 psi | °F | D648 | 114 – 182 | 134 – 201 |

| Compressive strength | psi | D695 | 1,420 – 16,000 | 1,420 – 16,000 |

* Technical Data is provided courtesy of UL Prospector (www.ulprospector.com) and IAPD (www.IAPD.org).

Data is to be considered representative and is provided for guidance only. All product performance must be verified by the user under actual application conditions.