Custom plastic sheets have applications in a huge array of industries, from medical facilities to retail stores. While general-use plastics may work in many commercial environments, there are certain industries that require high-performance materials that meet stringent requirements.

Some of these industries include aerospace, military, and manufacturing centers. If you or your clients require custom plastic sheets to suit specific needs within these categories, here’s a guide to the benefits and types of performance plastics that are most likely to suit your needs.

Performance Plastics: Aerospace and Military Grade Custom Plastic Sheets

Performance plastics are especially well suited to aerospace applications because they’re so lightweight. Planes and other aircraft need both interior and exterior components that promote aerodynamics and fuel efficiency. The lighter all the components are, the less fuel is needed to move the aircraft to its destination. Even seemingly small components like bulkheads and storage areas can make a major impact on these factors.

In addition to weight, performance plastics are a favorite among aerospace companies due to their ability to stand up to industry standards for flame, smoke, toxicity, and heat release. Basically, since aircraft produce high temperatures and contain people in enclosed areas, all materials included need to hold their original form even when exposed to fire or extreme heat. And they need to avoid emitting any toxic fumes or chemicals even when exposed to harsh environments.

Custom plastic sheets are also quite practical for aerospace applications due to their longevity and the low amount of maintenance needed to keep them in quality condition. Specifically, they don’t rust or corrode like metal components, and they can last years or decades, keeping repair and replacement costs low for aerospace companies.

Custom plastic sheets can be used in a huge array of applications within this industry, both inside and outside various aircraft. Common interior applications include cargo containers, bulkheads, dashboard enclosures, cockpit visors, beverage carts, countertops, window shades, dust panes, and signage. Outside, performance plastics can be used for various nose or cone shapes or components that fit along the aircraft exterior.

All the features that make custom plastic sheets a popular choice in the aerospace industry also apply to many military applications. In fact, plastics can also be used in many of the same applications within military aircraft. However, they can also be used in armored vehicle applications on the ground.

Specifically, plastics are often used in the production of armored glazing for vehicle windows. These systems provide added protection while still allowing clear visibility. Additionally, dashboards and vehicle windows must be resistant to fire, blast and fragment impact, and general weathering. Strong plastics like polycarbonate provide both the strength and durability needed to serve these high-performance applications.

Industrial and Commercial Focus: Custom Plastic Sheets

Beyond the specialized industries detailed above, custom plastic sheets must also meet stringent requirements for private manufacturing businesses and industrial facilities. There are seemingly endless applications within these industries, but here are a few specific use cases that may apply to industrial clients.

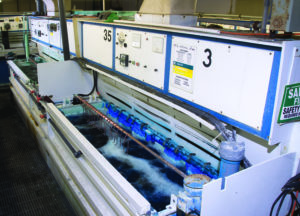

Custom plastic sheets are often employed in food and beverage processing, preparation, and packaging facilities. Food handling businesses must meet strict industry standards, including those set by the FDA, USDA, NSF, and 3-A Dairy. Many materials must also be heat and/or chemical resistant in order to withstand sterilization processes. There are a variety of plastics that meet these industry requirements and have the necessary qualities to facilitate sterilization. Plastic components can also be used in machinery in these packaging or handling centers. Plastics can offer good wear properties and allow machinery to run quieter at higher speeds. Specific materials vary based on the use case and items being handled, but some popular materials within this niche include HDPE, Polypropylene, and UHMW.

Industrial and electronic enclosures are all-encompassing structures that protect sensitive pieces of equipment. For example, they are often installed around electrical control panels that utility companies use to access entire grids. These enclosures can be installed in large facilities or even outdoors. Strong and durable plastics protect these important contents both from weather and intentional tampering. The exact materials used vary depending on the location of the enclosure and its contents. However, some popular materials that are usually strong and durable enough for these applications include polycarbonate, acrylic, ABS, and PAI.

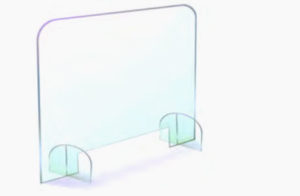

Machine guards are another common application for custom plastic sheets. These materials provide protection for workers in a huge array of manufacturing facilities and machine shops. They basically provide a protective barrier that prevents machinery or products from injuring operators. But they must still provide clear visibility to allow operators to control their machinery with skill and precision. These industrial machine guards are generally made of strong yet clear performance plastics. Popular options include polycarbonate, acrylic, and PETG. Similar plastics can also be used in other protective systems and barriers, including doors and windows or separators over secure or temperature-controlled areas.

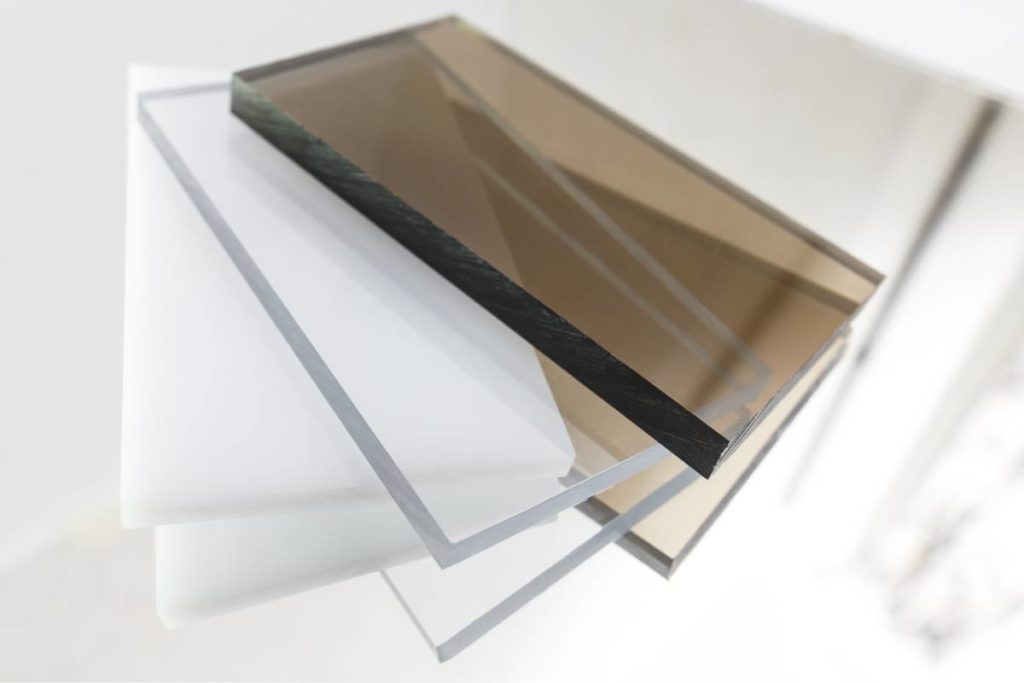

If you’re looking for custom plastic sheets to suit any of the high-performance applications detailed above, contact Polymershapes to discuss your needs today. We offer a huge range of quality materials, including polycarbonate, ABS, PET, UHMW, acrylic, and many more. Materials also come in a range of colors, finishes, and thicknesses to give your company the ideal sheets for your specific applications, and we connect users with value-added conversion and fabrication services to further customize your materials. Visit our website to find your local distribution center and reach out to our team to discuss your need for custom plastic sheets today.