Today’s cars contain more plastic than ever. Plastics weigh less than alternative materials such as metal, and less weight means less fuel consumption, which is attractive to consumers when deciding what model to purchase. It’s not just a marketing ploy – Federal Corporate Average Fuel Economy (CAFE) standards are becoming increasingly stringent, requiring car makers to improve the overall efficiency of their fleets. This further increases the drive to utilize lighter weight materials such as plastics.

Plastics are used in a multitude of applications in cars, including:

- Fuel tanks

- Cable insulation

- Carpet fibers

- Seating

- Wheels and tires

- Suspension bushings

- Dashboards

- Wheel covers

- Touch screens

- Headlamp lenses

- Truck bed liners

- Wheel well liners

- Mud flaps

- Fluid lines

- Internal transmission parts including gears

- Bumpers and other body parts

PTFE (Polytetrafluoroethylene)

PVC-Acrylic

Silicone and Adhesives

PPS (Polyphenylene Sulfide)

PI (Polyimide)

Polyurethane (PU)

PAI (Polyamide-imide)

PEEK (Polyetheretherketone)

PEI (Polyetherimide, ULTEM™)

Composites & Processing Aids

Nylon (Polyamide, PA)

Ultra High Molecular Weight Polyethylene (UHMW)

ABS (Acrylonitrile Butadiene Styrene)

LEXAN™ Polycarbonate Sheets

Acetal (Polyoxymethylene, POM)

Acrylic (Polymethyl Methacrylate, PMMA)

High Density Polyethylene (HDPE)

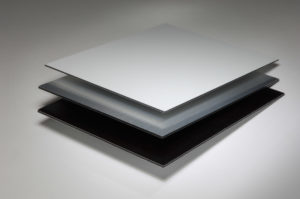

Aluminum Composite Material (ACM)

Polypropylene Sheet, Rod and Tube